Description

Sizes – parameters

| Size | Filtering surface | Maximum flow1 |

| 01: Ø 180 x 430mm | 01: 0,24 m2 – 7×32” | 01: 5 m3/h – 22 GPM |

| 02: 0180 x 810mm | 02: 0,48 m2 – 7x | 02: 10 m3/h – 44 GPM |

1For liquids with a diynamic viscosity of 1 mPa • s @ 20 °C

Maximum operating temperature

Polypropylene 90 °C (194 °F)

Recommended bag replacement P

0,5 bar ( 7,3 psi)

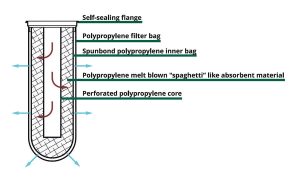

Material

Absorbent and filter bag

Finishing

Calendered surface

Flange type

Self-sealing polypropylene flange

Welded bag

Efficency

Filtration accuracy – micron rating

5; 1 0; 25; 50; 100; 200 μm